EH&S works with departments to make sure that chemicals are stored, used, and disposed of in accordance with federal and state regulations.

Departments that store chemicals are required to have a department-specific Chemical Hygiene Plan and a Contingency Plan that can be used in the event of an emergency. Departments must keep an inventory of chemicals under their control.

Researchers using hazardous chemicals are required to create and maintain a laboratory-specific Chemical Hygiene Plan in accordance with WAC 296-828, and keep an inventory of the chemicals in their lab.

Researchers/instructors and staff who use chemicals must follow all regulations, attend required trainings.

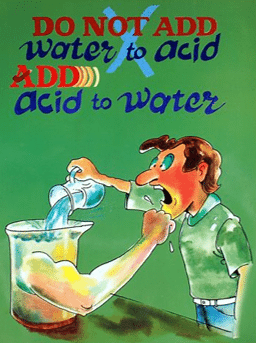

General Chemical Safety

Always wear safety goggles when working with hazardous chemicals!

Hazard Communication

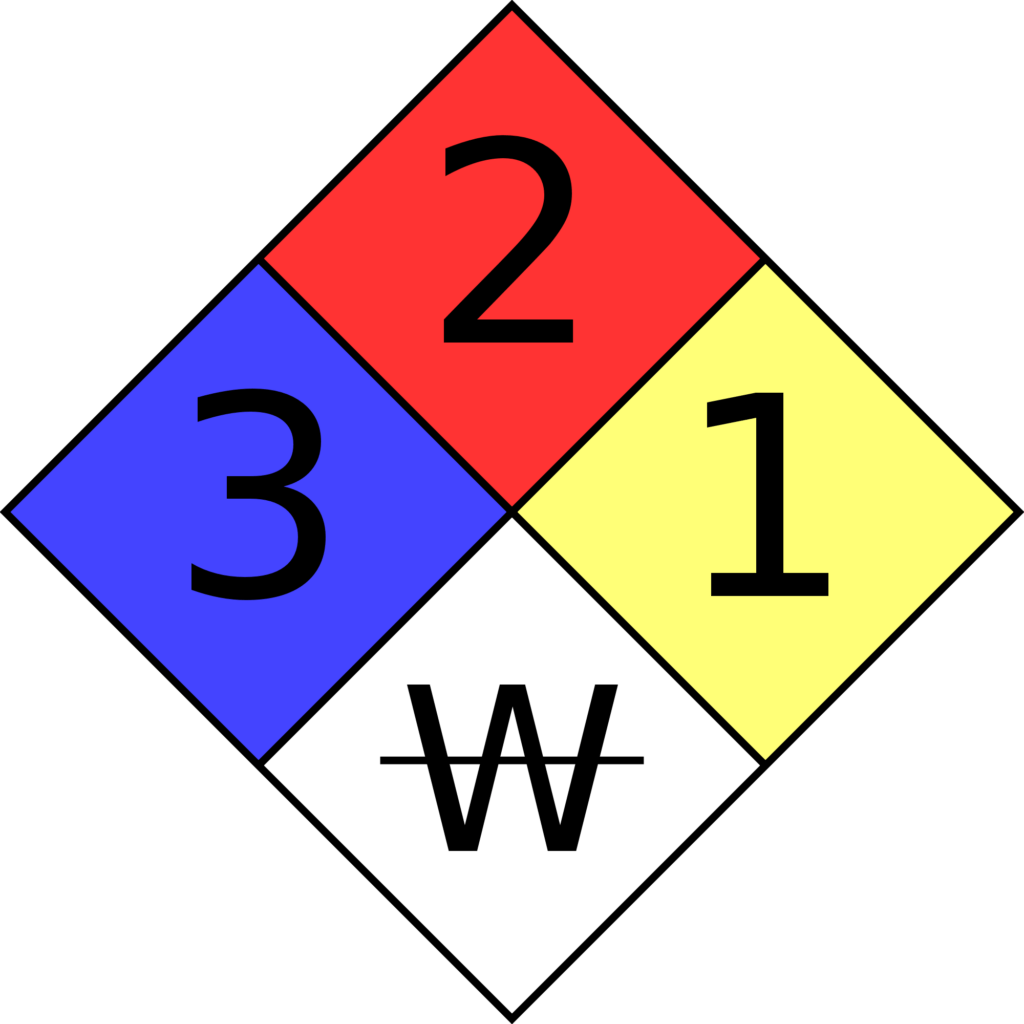

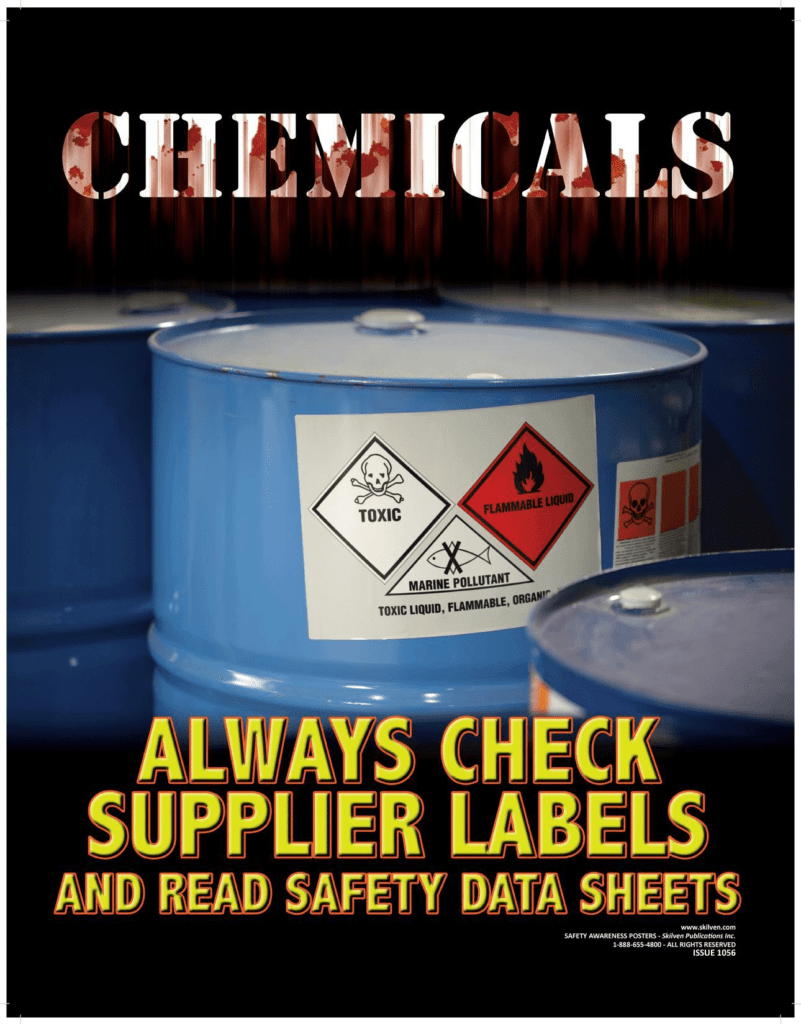

Hazard Communication (HazCom) is how we ensure that everyone who works with or around chemicals is aware of any hazards those chemicals pose. It consists of three parts:

- Hazard Communication Training

- Labeling/Signing of chemical materials

- Availability, knowledge, and use of Safety Data Sheets

Chemical Hygiene Plan

A Chemical Hygiene Plan (CHP) is a set of documents describing the types of hazards present in a department or laboratory and what procedures and precautions are used to promote safety while working with the hazards.

The information gathered in the CHP is useful for department and laboratory specific HazCom trainings. All departments and laboratories that work with hazardous chemicals are required to create and maintain a CHP.

The Chemical Safety Manual serves as the base of all EWU CHPs and contains a list of the other information that is needed to complete department, lab, or shop specific CHPs.

WAC 296-828 requires that hazardous chemical users document their safety procedures in a Chemical Hygiene Plan (CHP). For EWU departments, laboratories, and shops using chemicals, the CHP is created by combining information specific to each department, lab, or shop with information found in the Chemical Safety Manual.

CHPs must be accessible at all times to all personnel who work in areas containing hazardous chemicals.

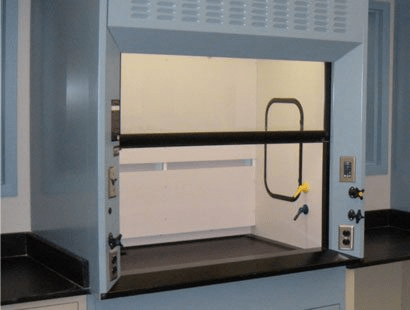

Fume Hoods

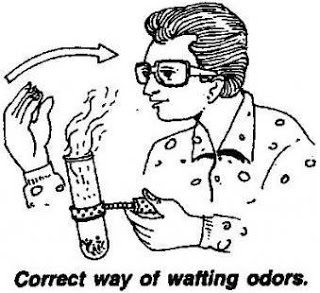

A fume hood is a ventilated enclosure that is designed to limit the user’s exposure to hazardous or toxic airborne materials. The sash can also be used to help protect the user from splashes or explosions.

The fume hood draws air in from the room and vents it outside so that clean air is continually pulled from behind the user and any hazardous airborne material inside the hood is kept out of the room.

Fume hoods are not for use with biohazardous materials because they vent outside without the necessary filtration to remove a biohazard.

Using a Fume Hood

It is important to use fume hoods properly to ensure your safety. When working in a fume hood:

- Keep all materials at least 6 inches behind the sash.

- Keep materials away from the sides of the fume hood so that air can flow past on both sides. Large equipment that must be put inside the hood should be elevated about two inches to allow air to flow under it.

- Only place necessary items inside the hood, keep it as clean as possible to allow for maximum airflow.

- Keep the sash as low as possible while working, and keep it closed when the hood is not being used.

- Move arms slowly when working in the hood to keep air turbulance to a minimum.

- Never put your head inside the fume hood!

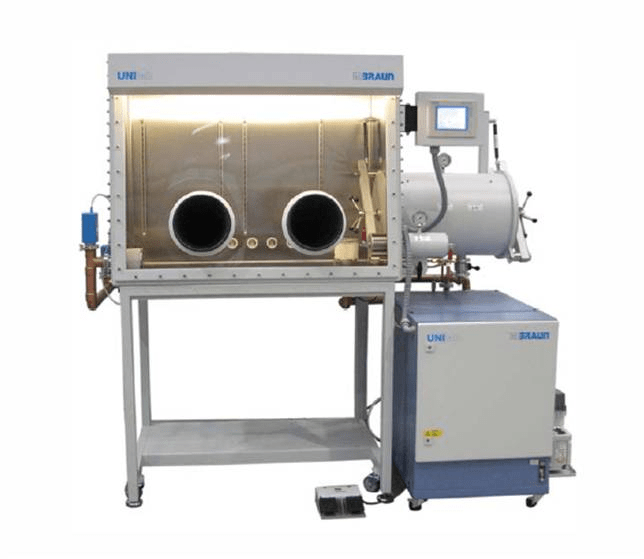

Glove Boxes

A glove box is a sealed container that can be used to work with chemicals that require a special atmosphere (e.g. argon, nitrogen, or a vacuum) or materials that are extremely toxic.

Make sure to follow all instructions your supervisor or instructor gives if you are working in a glove box.